It is important to use the right safety gloves for the right task. Different tasks can require different types of gloves. When it comes to the choice of Work gloves, it is important that you choose the one that fits you easily, does not provide any discomfort and helps you do your job while protecting your hands from the materials that may harm your skin.

Working gloves are required heavily in the manufacturing, chemical industry, steel works and the oil industry. Whether you are dealing with abrasive chemicals or lifting heavy stuff, working gloves are a must for protection. So much so that a lot of firms have it in their SOP’s that any hands-on field work could not be performed without working gloves. So check out this list of 10 best work gloves and let us know your favorite glove in the comments section below.

Potential hazards to hands and arms include skin absorption of harmful substances, chemical or thermal burns, electrical dangers, bruises, abrasions, cuts, punctures, fractures or amputations. Protective equipment includes gloves, finger guards and arm coverings.

Types of Protective Glove

There are many types of gloves available today to protect against a wide variety of hazards. The nature of the hazard and the operation involved will affect the selection of gloves. The variety of potential occupational hand injuries makes selecting the right pair of gloves challenging. In general, gloves fall into the following four categories:

- Leather, Canvas or Metal Mesh Gloves: These types of gloves protect against cuts, burns and punctures.

- Fabric and Coated Fabric Gloves: These types of gloves are made of cotton or other fabric. They generally protect against dirt, chafing and abrasions.

- Insulating rubber gloves: These gloves are used for protection against electrical hazards. For more information on insulating rubber gloves for electrical work, see Electrical Safety Protective Methods

- Chemical and liquid resistant gloves: When working with chemicals with a high acute toxicity, working with corrosive materials in high concentrations, handling chemicals for extended periods of time or immersing all or part of a hand into a chemical, the appropriate glove material should be selected, based on chemical compatibility. The following table includes major glove types and their general uses. This list is not exhaustive. For more information on chemical resistant glove selection, see PPE for Chemical Hazards or the Safety Data Sheet for a particular substance.

Other Considerations

There are several factors besides glove material to consider when selecting the appropriate glove. The amount of dexterity needed to perform a particular manipulation must be weighed against the glove material recommended for maximum chemical resistance. In some cases, particularly when working with delicate objects where fine dexterity is crucial, a bulky glove may actually be more of a hazard.

- Dexterity: Where fine dexterity is needed, consider double gloving with a less compatible material, immediately removing and replacing the outer glove if there are any signs of contamination. In some cases, such as when wearing Silver Shield gloves, it may be possible to wear a tight-fitting glove over the loose glove to increase the overall dexterity.

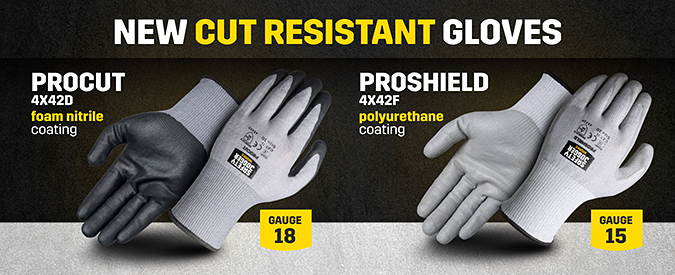

- Glove thickness, usually measured in mils or gauge, is another consideration. A 10-gauge glove is equivalent to 10 mils or 0.01 inches. Thinner, lighter gloves offer better touch sensitivity and flexibility, but may provide shorter breakthrough times. Generally, doubling the thickness of the glove quadruples the breakthrough time.

- Glove length should be chosen based on the depth to which the arm will be immersed or where chemical splash is likely. Gloves longer than 14 inches provide extra protection against splash or immersion.

- Glove size may also be important. One size does not fit all. Gloves which are too tight tend to cause fatigue, while gloves which are too loose will have loose finger ends which make work more difficult. The circumference of the hand, measured in inches, is roughly equivalent to the reported glove size. Glove color, cuff design, and lining should also be considered for some tasks.

Glove Inspection, Use and Care

All gloves should be inspected for signs of degradation or puncture before use. Test for pinholes by blowing or trapping air inside and rolling them out. Do not fill them with water, as this makes the gloves uncomfortable and may make it more difficult to detect a leak when wearing the glove.

Disposable gloves should be changed when there is any sign of contamination. Reusable gloves should be washed frequently if used for an extended period of time.

While wearing gloves, be careful not to handle anything but the materials involved in the procedure. Touching equipment, phones, wastebaskets or other surfaces may cause contamination. Be aware of touching the face, hair, and clothing as well.

Before removing them, wash the outside of the glove. To avoid accidental skin exposure, remove the first glove by grasping the cuff and peeling the glove off the hand so that the glove is inside out. Repeat this process with the second hand, touching the inside of the glove cuff, rather than the outside. Wash hands immediately with soap and water.

Follow the manufacturer’s instructions for washing and caring for reusable gloves.

I ordered on Friday evening and on Monday at 12:30 the package was with me. I have never encountered such a fast order processing.